VCY Y-Ball Check Valve

Application

VC Series Prevents the fluid from flowing back and ensures that if flows in only one direction, it can be used to prevent the loss of prime of the pump to avoid pipe-hammering in the food-processing, beverages, wine-making, oil-making, cosmetics, pharmacemical industries.

Materials

- Materials: AISI-304 or AISI-316L

- Gasket Material:Silicon, EPDM, PTFE, FPM, NBR

Valve seat and gasket comply with FDA 21CFR177.2600

Standard Design

- Standard Avaliable: DIN, SMS, ISO / IDF, BS / RJT, and ASME / BPE.

Technical Specification

- Size available: 1", 1.1/2", 2", 2.1/2", 3", 3.1/2", 4"

- Max. pressure: 10bar (147psi)

- Temperature range: 14 ~ 248°F (-10 ~ 120°C), EPDM

- Inside polishing: Ra 16 ~ 32μin (0.4 ~0.8μm)

- Connections: Weld, Thread, Clamp, DIN, SMS, RJT, IDF, ISO,

Each of the sizes of the Sanitary Stainless Steel Y-Ball Check Valve stocked have the following features:

Our valve comes standard with a Buna-N Ball and EPDM gasket but we also stock a Viton®ball or Teflon®Ball and can ship various sizes per your request. Upon shipment, each valve is capped and bagged with the alloy, size and heat number for full traceability.

The working principle behind the Sanitary Stainless Steel Y-Ball Check Valve or Y-Body Check Valve begins as liquid enters the run of the Y-Ball Check Valve, the ball lifts up into the branch, thus allowing full flow of product. Upon recession of flow, valve pressure equalizes, then the ball returns and resides near the smallest area of the run, preventing back flow. If a reverse flow situation arises, opposing pressure of the product will place the ball against the run of the valve preventing back flow whether the valve is in a horizontal or vertical position.

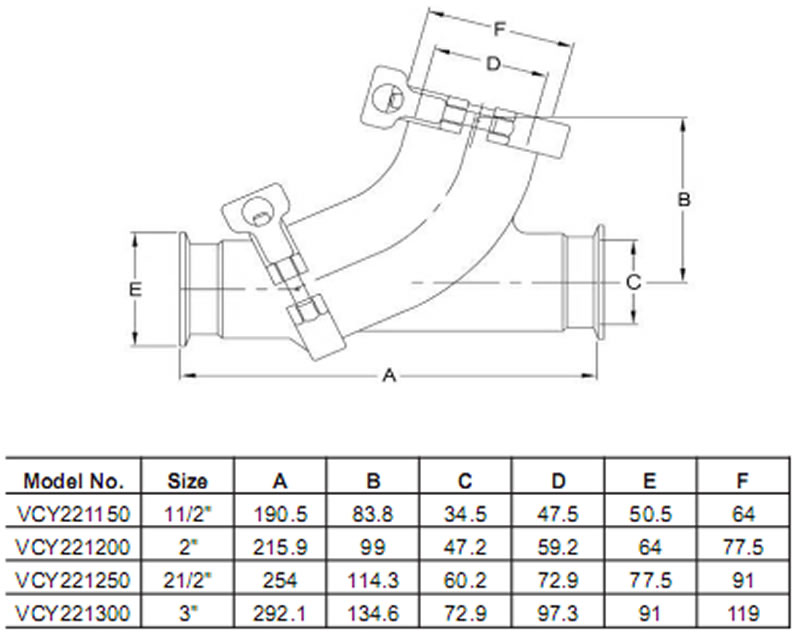

Drawing